Let me kick of this section of the forum with my newest creation.

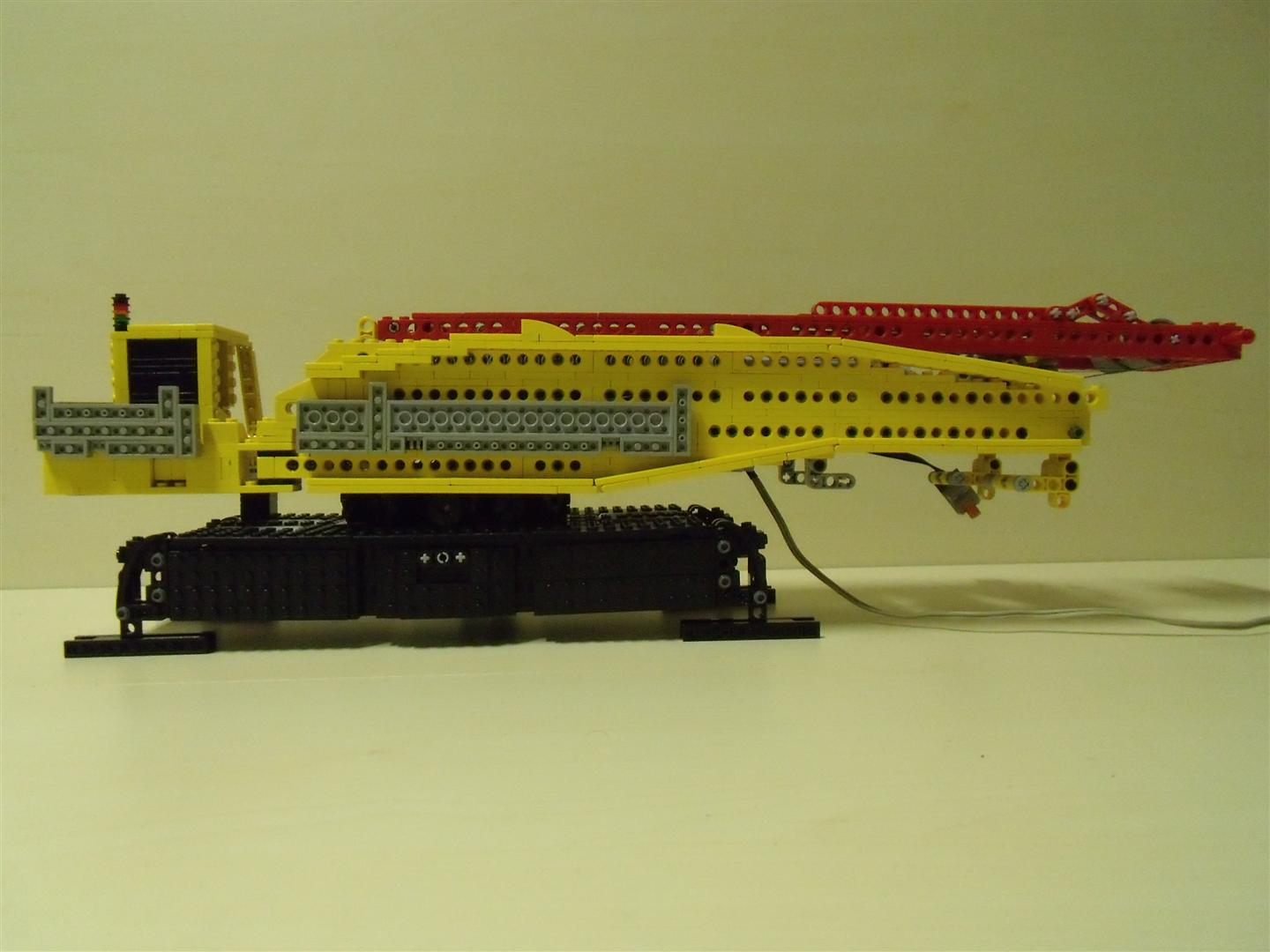

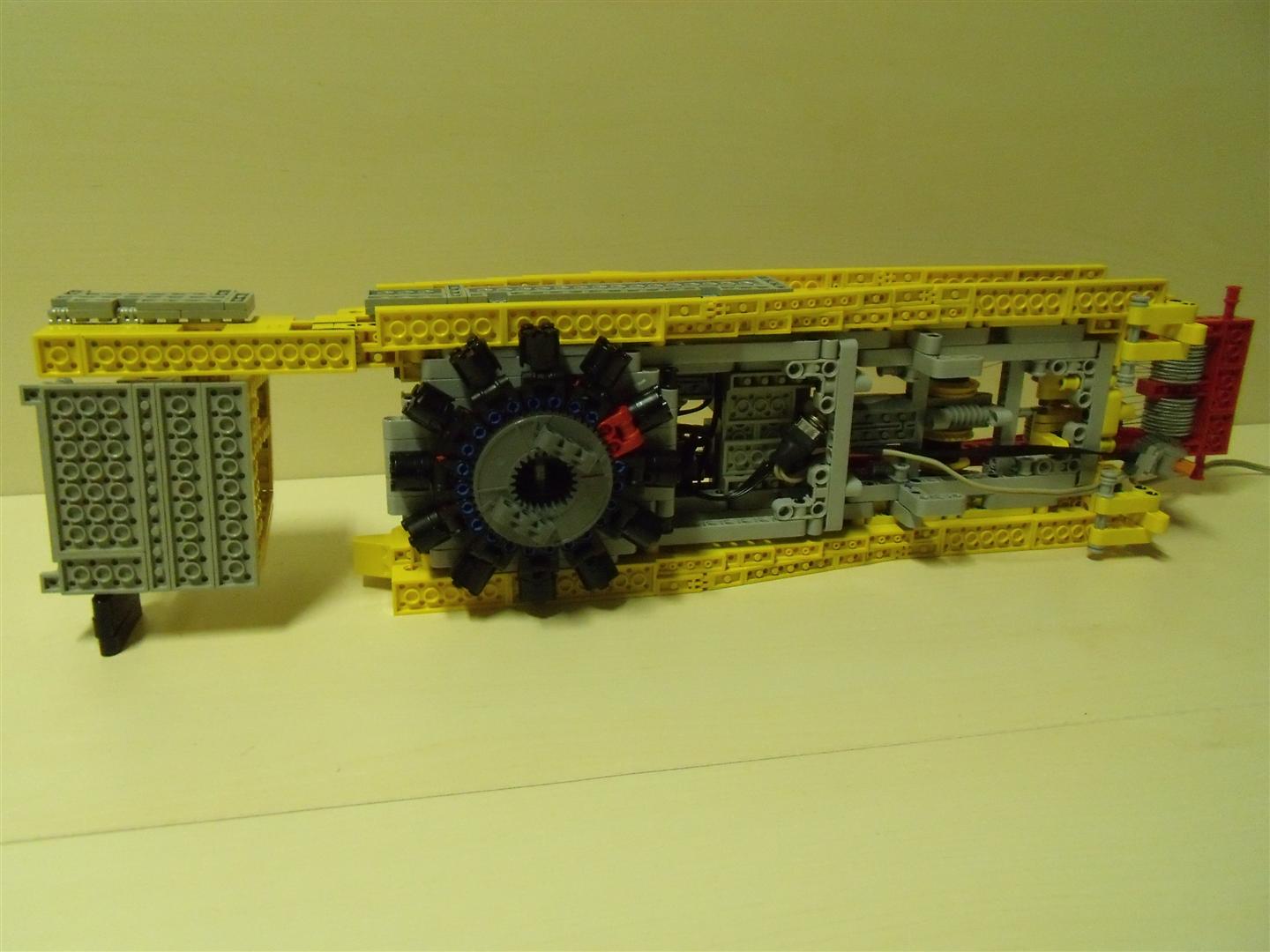

It is a 1:25 scale model of a Demag CC1800-1.

Some dimensions:

Super lift boom_1,2 meter

Main boom_2,0 meter

Jib boom_1,0 meter

Ballast on super structure_0,6 kilograms

Ballast on super lift carrier_ 4 kilograms

It carries the following motors:

A-frame_1 M motor

Winch 1_1 M motor

Winch 2_1 M motor

Super lift_1 M motor

Luffing jib_1 M motor

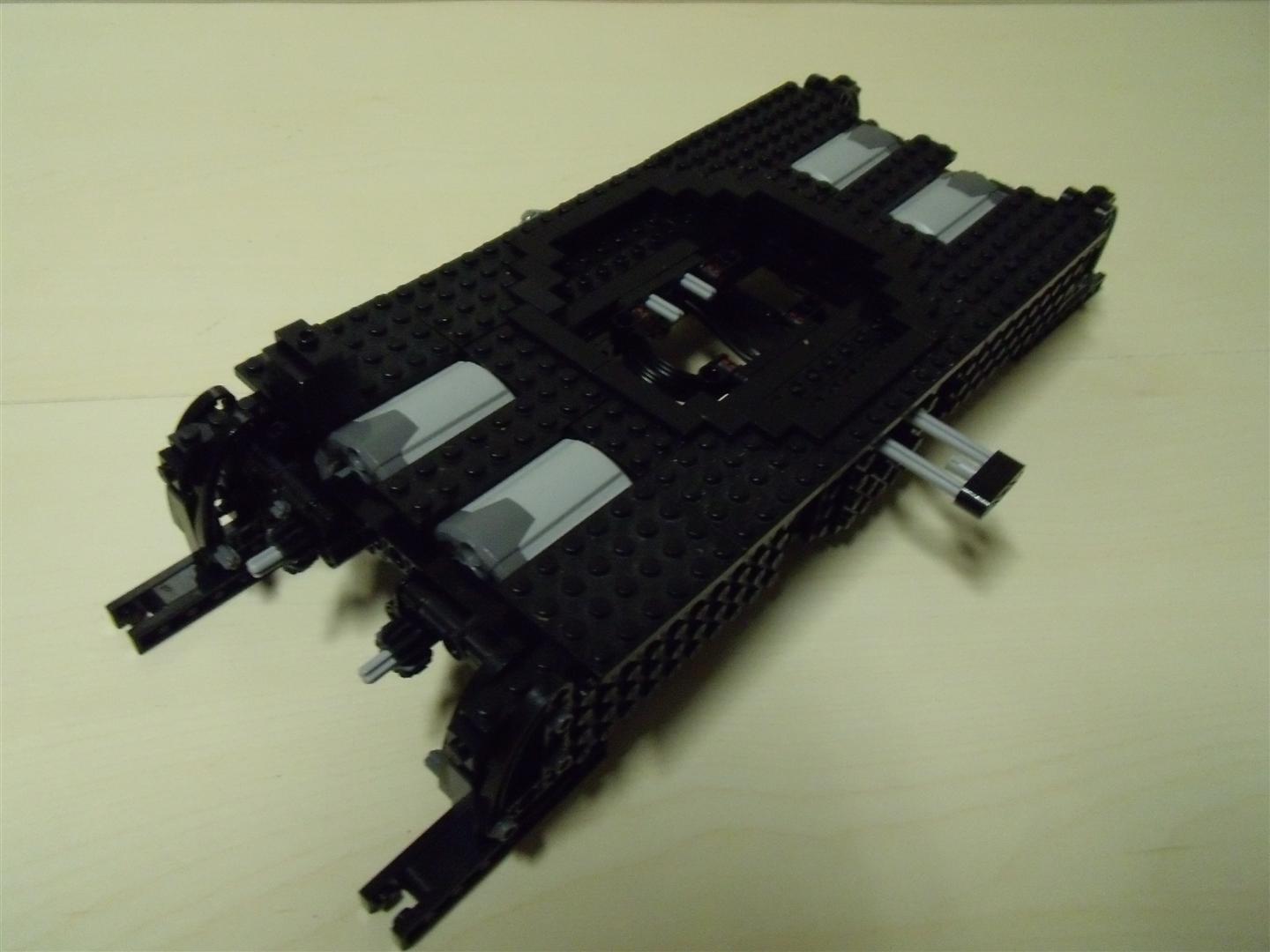

Tracks_4 XL motor

Ballast carrier_1 XL motor

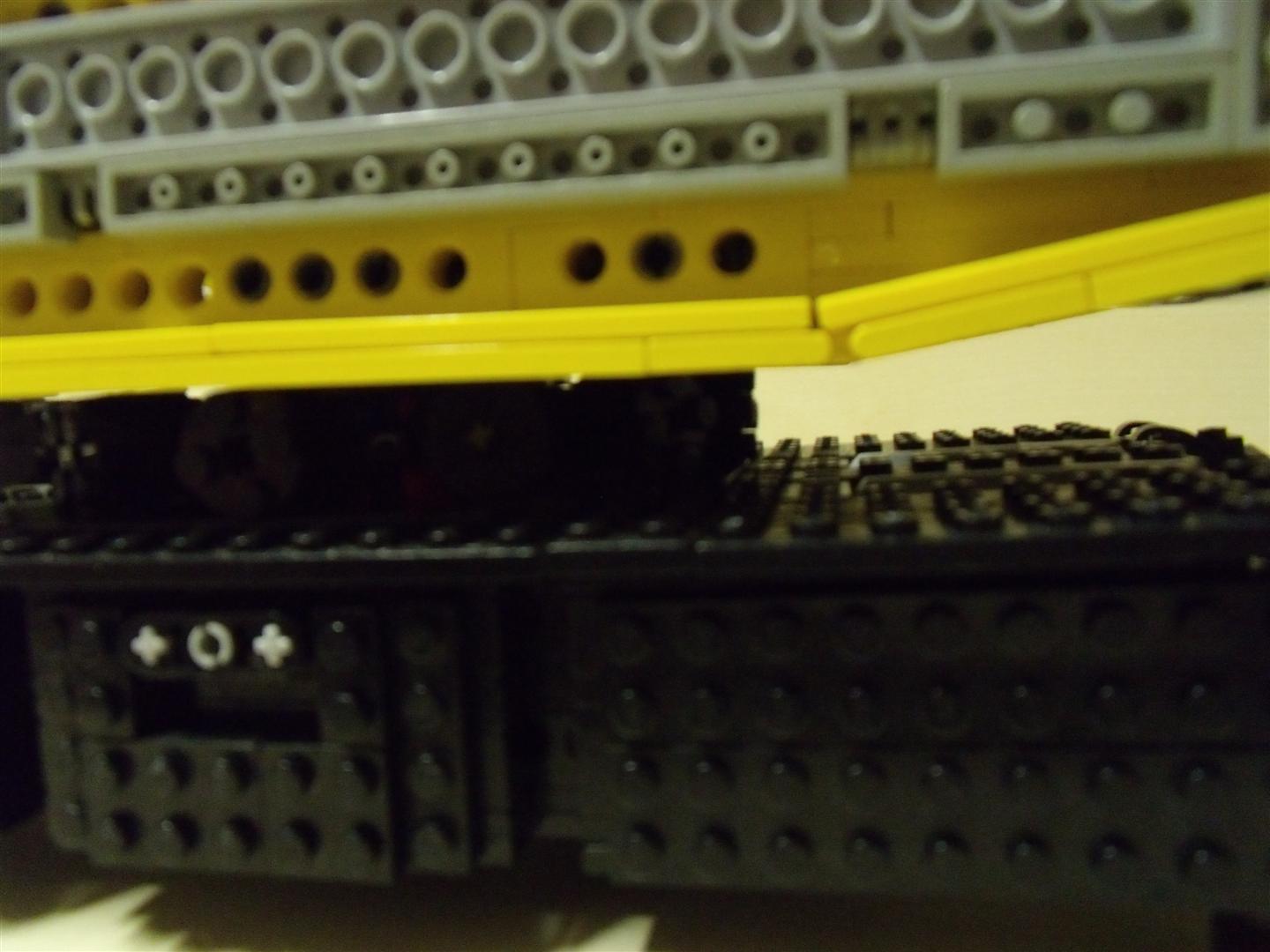

The crane slews with the wheels on the ballast carrier, slewing through the center of the crane was too weak.

Power is supplied through a converter, so no use of fooling around with battery boxes.

With the current ballast it is possible to raise and lower the boom in the current setup.

Work to do:

1. 1 more meter of jib.

2. Build tracks.

3. Enhance superlift carrier.

It is work in progress, so more to come.

Greetz,

As

.gif)

.gif)

.gif)

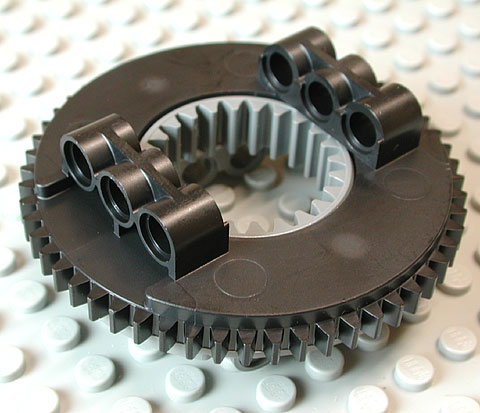

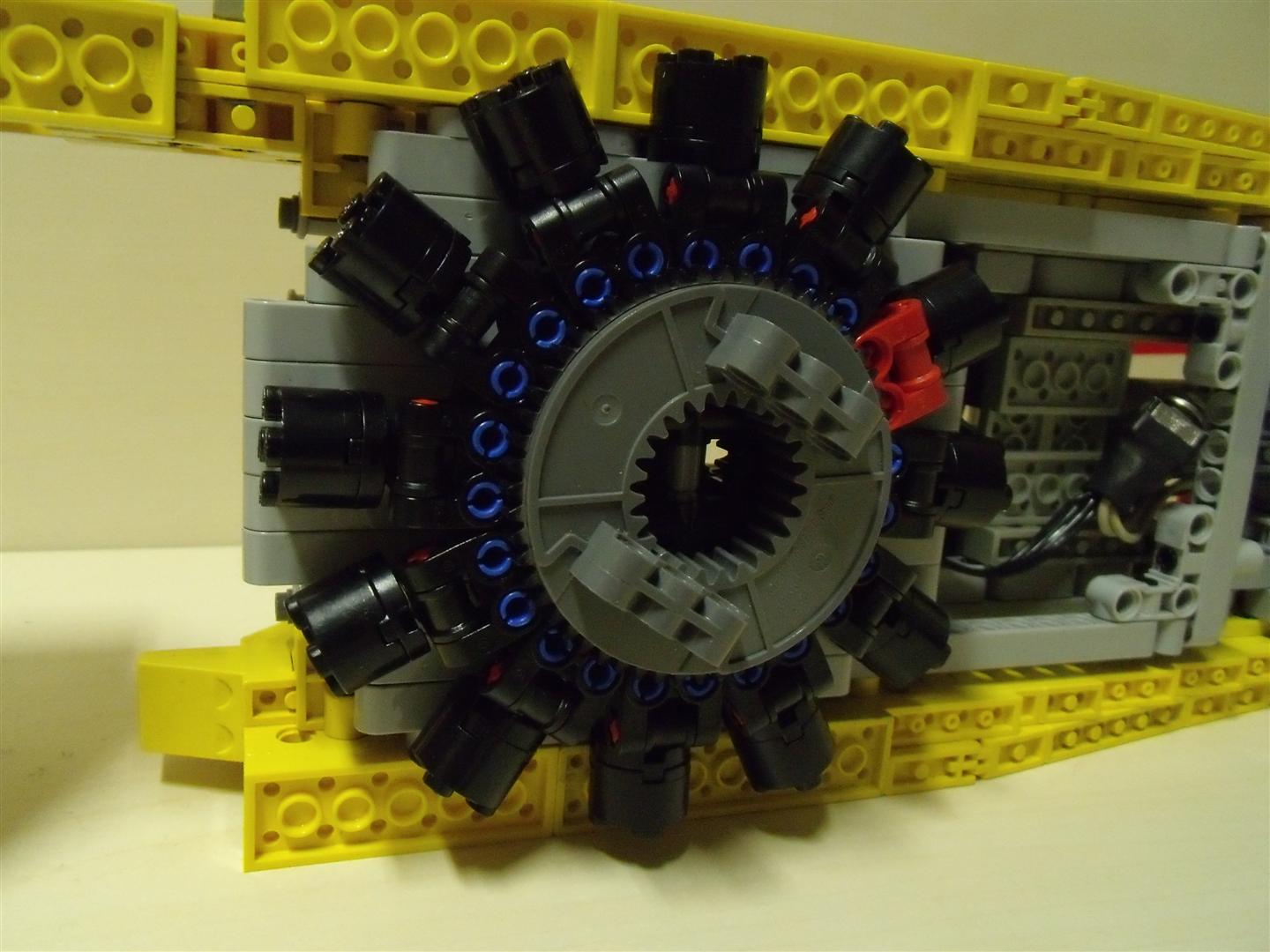

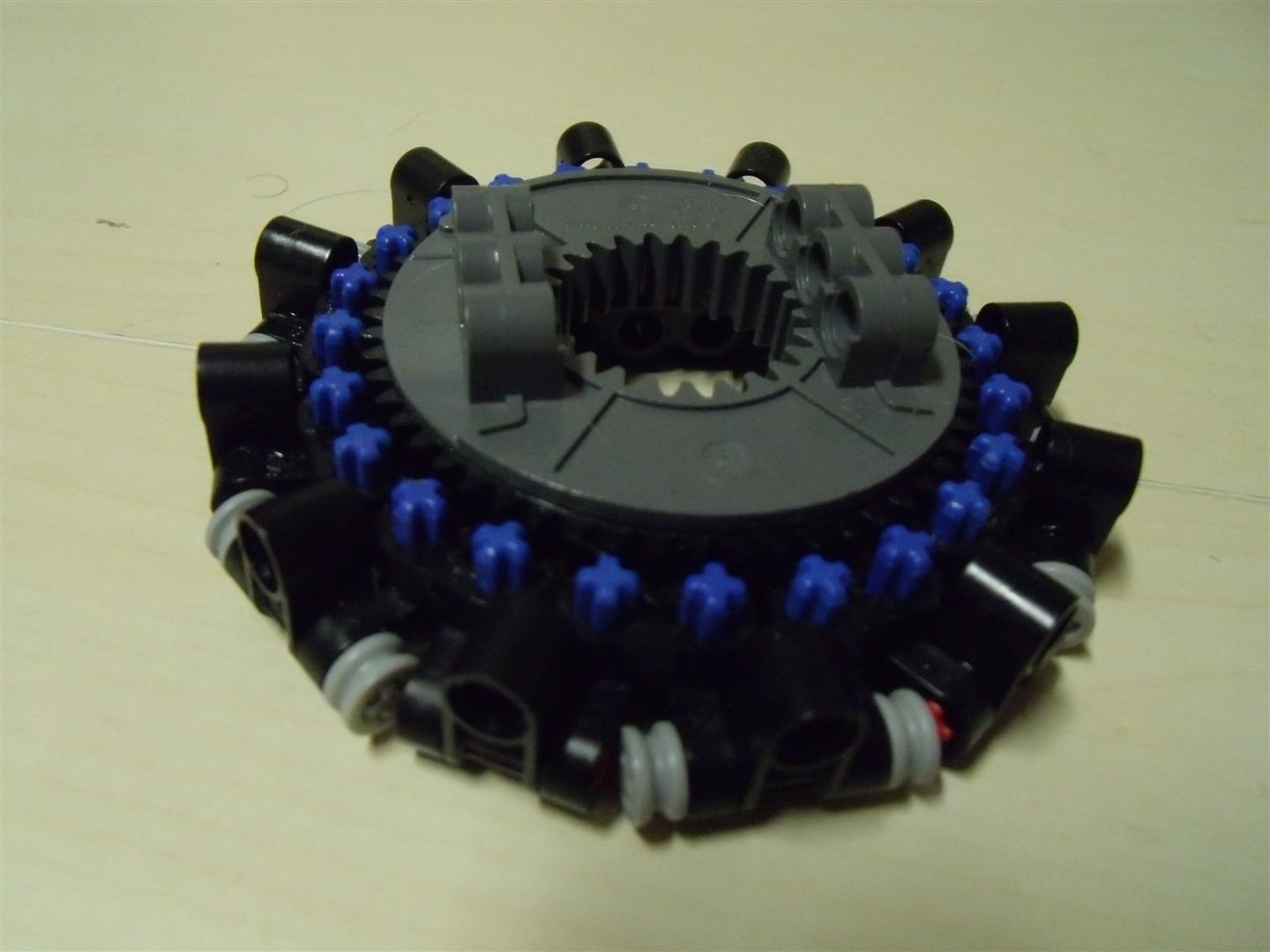

on the grey inside of the turntable

on the grey inside of the turntable